Using Mineral Cartridge Qorveh in Concrete Powder

Mahmoodreza Keymanesh1 , Ali Heydari2 , Nasrin Heydari Borujeni3 * and Ali Motamedi4

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.62

Concrete has the greatest consumption in civil structures today. In recent years, extensive research has been conducted for the purpose of mixing high-strength concretes. Reactive powder concretes (RPCs) are the ultimate result of concrete stakeholders’ efforts in this regard. This new type of super strong concrete is called “reactive powder concrete” due to its fine powder and pozzolanic constituents as well as the many hydraulically active materials used in its combination. As using pozzolanic materials in this type of concrete can be useful for environmental protection, reducing costs, and improving certain concrete properties, authors conducted an empirical feasibility study into the possibility of using a mineral lightweight aggregate called Qorveh, a natural pozzolan created by volcanic lava, as the active pozzolan in powder concrete. To this end, through a planned experimental procedure, concrete specimens containing Qorveh lightweight aggregate were prepared in different proportions to substitute cement in concrete. Analysis of the obtained results showed that using this mineral aggregate under normal curing conditions (adding water at 20 C), was highly practical and efficient.

Copy the following to cite this article:

Keymanesh M, Heydari A, Borujeni N. H, Motamedi A. Using Mineral Cartridge Qorveh in Concrete Powder. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.62

Copy the following to cite this URL:

Keymanesh M, Heydari A, Borujeni N. H, Motamedi A. Using Mineral Cartridge Qorveh in Concrete Powder. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=10789

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2014-11-20 |

|---|---|

| Accepted: | 2014-12-03 |

Introduction

Reactive powder concrete (RPC) is a new type of super strength concrete. As a result of substituting coarse concrete aggregates with fine aggregates, a homogeneous concrete with excellent microscopic structure is obtained with low porosity and very high durability.

As compared with conventional concrete, RPCs have several advantages including high compressive and flexural strength as well as durability and energy absorption; very high corrosion and wear resistance; and very low permeability. This concrete consists of particles with similar moduli of elasticity which are granulated for producing greater density and increasing considerably the ultimate strength of the material.

|

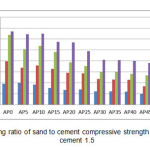

Figure1: The mixing ratio of sand to cement compressive strength mixing ratio sand to cement 1.5 |

Due to the relatively recent advent of powder concrete, few reports have been presented at the global or domestic level (inside Iran) on research and experimental studies regarding its mixing.

Since producing a ton of cement requires 4 gigajoules of energy, and since the same operation releases approximately one ton of CO2 and 2.3 kg of NOx into the atmosphere (Peidaesh, 2006), we can conclude that cement production is responsible for emission of a considerable volume of greenhouse gases into the atmosphere at the global level.

|

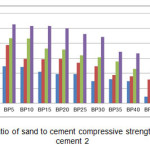

Figure2: The mixing ratio of sand to cement compressive strength mixing ratio sand to cement 2 |

Reduced cement consumption is also economically important. The high global price of

cement increases the cost price of concrete also. For this reason, substituting cement with cheaper materials having suitable properties has flourished (Isapur & lekdust, 1959).

This study investigates the effect of substituting part of the cement content of reactive powder concrete with Qorveh mineral lightweight aggregate, a natural pozzolan. Using pozzolanic materials can help environmental protection, reduce costs, and improve certain properties in concrete. The positive effects of pozzolanic materials on the durability of concrete and in reducing hydration temperature for large-volume concrete placement have turned pozzolans into main concrete constituents.

Due to Iran’s rich pozzolan resources, studying the exact mechanical and durability characteristics of these materials and considering them for use in the cement industry would be appropriate.

Mineral lightweight aggregates are natural pozzolanic materials made of volcanic lava exhibiting good sound and heat insulation properties. In combination with cement, these materials exhibit high water retaining capacities which leads to increased strength of the concrete.

There are rich resources of mineral lightweight aggregates in Ardebil, Eastern Azarbayejan (particularly in the Bostan Abad region near Tabriz), Qorveh, Kermanshah, Kerman, Sistan and Baluchestan, a few regions in Khorasan Province, and the outskirts of the Alborz Mountains.

The concrete made of mineral lightweight aggregates not only is light in weight, but also exhibits high strength as well as resistance against different environmental conditions. The strategic significance of this product is obvious due to the following properties: high porosity, being free from pests and pathogens, structural stability, incompressibility, long life and durability, permeability and high water retaining capability, very light weight, low density, good heat and sound insulation, fire resistance, heat/clod/remelting resistance, being neutral chemically, and being environmentally friendly. On the other hand, applications of this pozzolan in road making; construction works (lightweight concrete, filler between floors, etc.); and dam, bridge, and tunnel construction; as well as applications in agriculture (for cultivation of green house plants and for use in dry soils to retain water) also prove its strategic importance. The mentioned properties and applications are of vital importance to any country (Hossain, 2004; Yasar, Atis, Kilic, & Gulsen, 2003).

In large-volume concrete placement during dam construction or underpinning, the high temperatures in concrete resulting from the quick hydration reaction are a major concern since they can cause thermal cracks in concrete. Using Qorveh lightweight aggregate as an active pozzolan can prolong hydration and thus considerably lower hydration temperatures.

Extensive research has been conducted in recent years for obtaining high strength concretes. A high strength concrete has a compressive strength of 50-120 MPa. Although high strength concrete is regarded as a relatively modern material, the idea of developing it has been subject to major modifications.

Reactive powder concrete is a super high strength concrete registered in 1994 by a French company. Before that, high strength concrete (HSC) used to be the best solution for high strength/performance applications. The main improvement in powder concrete as compared with cement concrete is its particle homogeneity, high porosity, and suitable microscopic structure.

Powder concrete was first used in a pedestrian bridge in Sherbrook, Canada. The greatly reduced dimensions and light weight of the concrete sections are the specific features of this structure (Lee, Wang, & Chiu, 2007).

Table1: Comparison of mechanical properties of concrete powder with 80 MPa strength concrete (Kosmatka, Panarese, & Association, 2002).

|

Powder Concrete |

Concrrete with Strength 80MPa |

Unit |

Characteristic |

|

200 |

80 |

MPa |

Compressive Strength |

|

40 |

7 |

MPa |

Bending Strength |

|

8 |

- |

MPa |

Tensile Strength |

|

60 |

40 |

MPa |

Modulus Alasysyth |

|

30 |

>1 |

103 J/m2 |

Bending Tolerate |

|

0 |

2 |

mm |

Permeability |

|

1.2 |

275 |

10-12 m2/s |

abrasion |

Pozzolans are silica or silica-aluminate materials which do not exhibit adhesive properties by themselves. However, as very fine particles, they can react chemically with calcium hydroxide (in the presence of lime or cement) at ambient temperatures in a humid environment to produce compounds which have adhesive and cementing properties (Committee, 2004).

As a result of the chemical reaction between pozzolan and calcium hydroxide (Ca(OH2)) (which can be formed from hydration of the main phases in cement or exist as a free agent in concrete), hydrated calcium silicate is formed. Unlike calcium hydroxide, calcium silicate has a crystalline structure with weak molecular forces between its crystal layers. It is soluble in water, can decompose concrete, and is a stable substance which can improve the mechanical properties of concrete. CaOH2 and pozzolan do not have adhesive properties by themselves; however, they chemically react to produce calcium silicate with cementing properties (Ahmadi & Shekarchi, 2010; Sabir, Wild, & Bai, 2001)

The word “pozzolan” is derived from Pozzoli, a region in Italy where pozzolan was first discovered circa 2000 years ago. As compared with a concrete containing Portland cement, it takes longer for a pozzolanic concrete to reach its early strength. However, the ultimate strength of the latter either equals or exceeds that of the Portland cement concrete. Mixing cement with pozzolan produces a type of cement called “pozzolanic cement”.

Regarding their origin, pozzolans are divided into two groups: natural pozzolans and artificial pozzolans. Mineral lightweight pozzolan is a natural pozzolan resulting from volcanic lava. Containing lightweight granulates; natural pozzolan is a good sound and heat insulator.

In the past, Roman engineers would use natural pozzolan for building ancient buildings. In addition to using it domestically, Iran currently exports mineral lightweight aggregates to other countries including the United Arab Emirates and Saudi Arabia.

Two kinds of mineral lightweight aggregate are most used in Iran: 1) scoria, and 2) pumice.

Scoria

This mineral lightweight aggregate can be found along a strip ranging from Azarbayejan to Kordestan. Scoria is known by the name Qorveh inside Iran since Qorveh region is one of the most important sources of scoria in this country.

Pumice: This kind of mineral lightweight aggregate is mostly found in the areas surrounding the Alborz Mountains, particularly in Central Alborz and Bostan Abad near Tabriz. Pumice has a lower quality than scoria.

The aim of this research to reach optimum mechanical properties of high performance concrete with the use of common materials in domestic mines, reducing the cost of bulk concrete construction as well as help the environment.

Materials and Methods

As a new powder concrete was mixed in this study, the chemical properties of the constituents had to be obtained. These are given in Table 2. The constituents of this concrete are:

Table2: Chemical properties of materials

|

Cement |

Powder Sand |

mineral cartridge Qorveh |

Chemical Propertice |

|

21.5 |

0.41 |

71.4 |

SiO2 |

|

5 |

0.09 |

13.75 |

Al2O3 |

|

4 |

0.06 |

2.11 |

Fe2O3 |

|

64.70 |

54.92 |

3.62 |

CaO |

|

- |

0.01 |

2.75 |

Na2O |

|

- |

0.01 |

2.45 |

K2O |

|

≥1.7 |

0.38 |

0.7 |

MgO |

|

- |

0.007 |

0.264 |

TiO2 |

|

- |

0.019 |

0.029 |

MnO |

|

- |

0.096 |

0.093 |

P2O5 |

|

≥1.7 |

0.085 |

0.003 |

SO3 |

|

≥1.3 |

43.69 |

2.49 |

L.O.I |

- Aggregate: Quartzitic sand and broken quartzite are commonly used in powder concrete. However, mixing this concrete is costly and requires a great amount of energy. To reduce costs, we used the powdery sand waste produced in Esfahan’s stonecutting workshops with a maximum grain size of 600 micrometers which was in compliance with powder concrete specifications.

- Cement: To reduce hydration temperature and improve efficiency in relatively high-volume concrete placements, we used Type 2 Shahrekord Cement.

- Water: Drinking water in Shahrekord University (which complies with ASTM C49-83) was used in mixing the concrete.

- Super plasticizer: A polycaboxylate-based super plasticizer was used in the proposed cement in compliance with ASTM C-494 and ISIRI-2930 standards.

- Pozzolan: The Qorveh mineral lightweight aggregate (ground to pass completely through mesh No. 200) was used as the pozzolanic constituent

To devise mix designs, the optimum ratios of the super plasticizer to cement and water to cement (i.e. adhesive materials) were determined through several tests before mixing the concrete for the main specimens.

Overall, 20 mix designs were provided: 10 with sand to cement ratios of 1.5 and 10 with sand to cement ratios of 2. In each mix design, three 5cm x 5 cm x 5 cm specimens (cubic in shape) were mixed to test the compressive strength of the powder concrete at the following ages: 1, 3, 7, and 28 days. Thus, a total of 240 specimens were prepared.

The optimum ratio of super plasticizer to cement was obtained as 2%. The optimum water to cement ratios for the sand to cement ratios of 1.5 and 2 were obtained as 35% and 40% respectively.

The prepared specimens were removed from their molds after 24 hours and cured in water at 20 C until the start of the tests.

The implemented mix designs are presented in Tables 3 and 4.

Table3: Mix designs ratio of sand to cement (adhesive materials) 1.5 (kg / m3)

|

Super plasticizer (SP) |

Powder Sand (S) |

Water (W) |

Cement (C) |

Mineral Cartridge Qorveh (P) |

SP/Ct |

W/Ct |

P/Ct |

Design |

|

15 |

1129 |

263 |

753 |

0 |

2% |

35% |

0% |

AP0 |

|

15 |

1129 |

263 |

715 |

38 |

2% |

35% |

5% |

AP5 |

|

15 |

1129 |

263 |

677 |

75 |

2% |

35% |

10% |

AP10 |

|

15 |

1129 |

263 |

640 |

113 |

2% |

35% |

15% |

AP15 |

|

15 |

1129 |

263 |

602 |

150 |

2% |

35% |

20% |

AP20 |

|

15 |

1129 |

263 |

564 |

188 |

2% |

35% |

25% |

AP25 |

|

15 |

1129 |

263 |

527 |

226 |

2% |

35% |

30% |

AP30 |

|

15 |

1129 |

263 |

489 |

263 |

2% |

35% |

35% |

AP35 |

|

15 |

1129 |

263 |

452 |

301 |

2% |

35% |

40% |

AP40 |

|

15 |

1129 |

263 |

414 |

339 |

2% |

35% |

45% |

AP45 |

In naming, Ct symbol accumulation pozzolan cement (adhesive) and A symbol of the mixing ratio sand to cement 1,5.

Table4: Mix designs ratio of sand to cement (adhesive materials) 2 (kg / m3)

|

Super plasticizer (SP) |

Powder Sand (S) |

Water (W) |

Cement (C) |

Mineral Cartridge Qorveh(P) |

SP/Ct |

W/Ct |

P/Ct |

Design |

|

15 |

1110 |

259 |

740 |

0 |

2% |

40% |

0% |

BP0 |

|

15 |

1110 |

259 |

703 |

37 |

2% |

40% |

5% |

BP5 |

|

15 |

1110 |

259 |

666 |

74 |

2% |

40% |

10% |

BP10 |

|

15 |

1110 |

259 |

629 |

111 |

2% |

40% |

15% |

BP15 |

|

15 |

1110 |

259 |

592 |

148 |

2% |

40% |

20% |

BP20 |

|

15 |

1110 |

259 |

556 |

185 |

2% |

40% |

25% |

BP25 |

|

15 |

1110 |

259 |

518 |

222 |

2% |

40% |

30% |

BP30 |

|

15 |

1110 |

259 |

481 |

259 |

2% |

40% |

35% |

BP35 |

|

15 |

1110 |

259 |

444 |

296 |

2% |

40% |

40% |

BP40 |

|

15 |

1110 |

259 |

407 |

333 |

2% |

40% |

45% |

BP45 |

Results

Compressive strength is the most important property of concrete and can be used as an index of concrete quality. The results obtained for concretes containing different percentages of Qorveh mineral lightweight aggregate are compared in Diagrams 1 and 2 with those obtained for the control specimens at the following ages: 1, 3, 7, and 28 days.

The results for each age were obtained by taking the mean value for three compressive cubic specimens with 5 cm dimensions.

As can be inferred from Diagrams 1 and 2, compressive strengths of the 28 day old specimens are closer to those of the control specimens as compared with the compressive strengths of the 7 day old specimens. In some specimens, the compressive strengths even exceeded those of the control specimens.

The diagrams show that, due to their higher cement content, concrete specimens with a lower sand to cement ratios (equal to 1.5 in this study) exhibit higher strengths than those with higher sand to cement ratios.

Moreover, as pure cement sets earlier than pozzolanic cement, the specimens with lower Qorveh aggregate to cement ratios exhibited lower strengths at the initial stages of aging. At greater concrete age values, the specimens’ strength steadily increased since the mineral lightweight aggregate started reacting with the cement.

Considering the overall performance of the pozzolans at earlier ages as well as the powder concrete’s structure and constituents, we expect the increasing trend in concrete strength to accelerate after the fourth week.

Discussion

Today, using new materials in concrete has become a routine procedure. New materials for substituting aggregates or cement in concrete are added for the purpose of protecting the environment, introducing economic savings, or improving concrete properties.

- Qorveh mineral lightweight aggregate possesses all the required parameters as an active pozzolan, and, therefore, can substitute cement in powder concretes. Thus, the amount of cement used in concrete mixing is reduced, leading to reduced initial costs in concrete curing as well as reduced CO2 emissions (due to cement production) in the atmosphere.

- The chemical compounds in Qorveh mineral lightweight aggregate comprise three main oxides, namely, silicon oxide, aluminum oxide, and iron oxide, the total percentage of which amounts to 87.26%, a very desirable percentage for a pozzolanic material. On the other hand, since silicon oxide alone accounts for 71.4% of these oxides, significant increases in concrete strength are expected at more advanced ages.

- Due to the fact that Type 2 cement exhibits good corrosion resistance against simultaneous chlorine and sulphate corrosive agents, and since Qorveh aggregate contains a very low percentage of sulphur in its chemical compounds, we conclude that the new powder concrete in this study, in addition to the above mentioned advantages, is also resistant against sulphidation.

- Considering the general situation regarding increased concrete strength in the early days (up to 28 days), we can conclude that as compared with the control specimens, the pozzolanic specimens exhibit a lower increase in their compressive strength at earlier ages. Such a behavior confirms that determining the optimal pozzolan percentage based on strengths obtained from long-term tests can provide more reliable results than those obtained from short-term tests (i.e. tests conducted during the first few weeks after concrete mixing).

References

- M. Concrete and its interaction with the environment. Second International Conference on Concrete and Development. Tehran (2006).

- Isapur. S, Malekdust. J. Compare the mechanical properties of concrete containing different pozzolan. Fifth Annual Conference on Concrete Iran. Tehran (1959).

- Ahmadi, Babak, & Shekarchi, Mohammad. Use of natural zeolite as a supplementary cementitious material. Cement and Concrete Composites, 32(2), 134-141 (2010).

- Committee, ASTM. ASTM C 618 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete. Annual Book of ASTM Standard, Section, 4, (2004).

- Hossain, Khandaker M Anwar. Properties of volcanic pumice based cement and lightweight concrete. Cement and Concrete Research, 34(2), 283-291.

- Kosmatka, Steven H, Panarese, William C, & Association, Portland Cement. Design and control of concrete mixtures. (2002).

- Lee, Ming-Gin, Wang, Yung-Chih, & Chiu, Chui-Te. A preliminary study of reactive powder concrete as a new repair material. Construction and Building Materials, 21(1), 182-189 (2007).

- Sabir, BB, Wild, S, & Bai, J. Metakaolin and calcined clays as pozzolans for concrete: a review. Cement and Concrete Composites, 23(6), 441-454 (2001).

- Yasar, Ergul, Atis, Cengiz Duran, Kilic, Alaettin, & Gulsen, Hasan. Strength properties of lightweight concrete made with basaltic pumice and fly ash. Materials Letters, 57(15), 2267-2270 (2003).